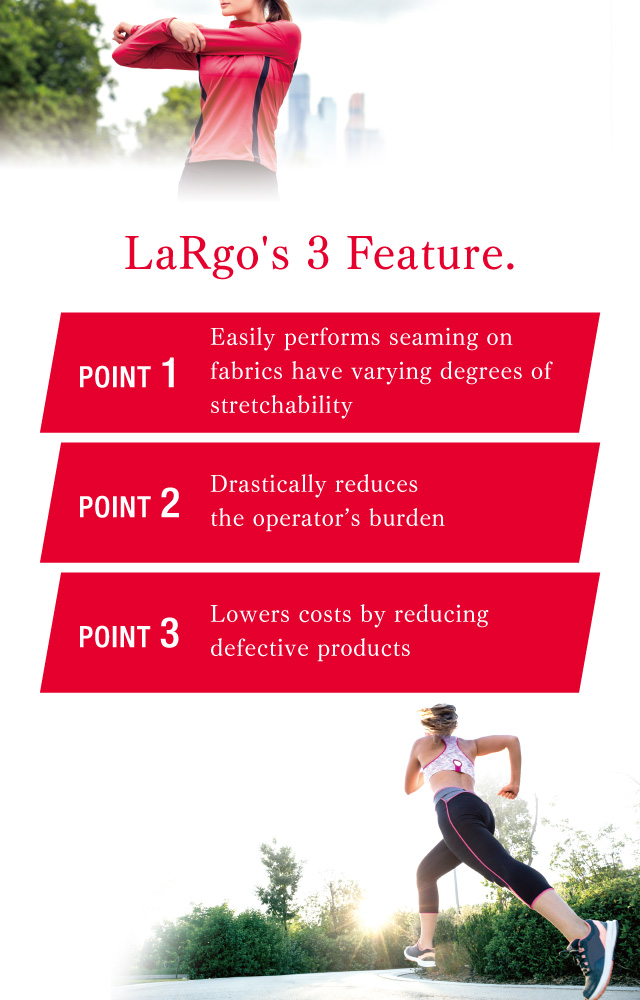

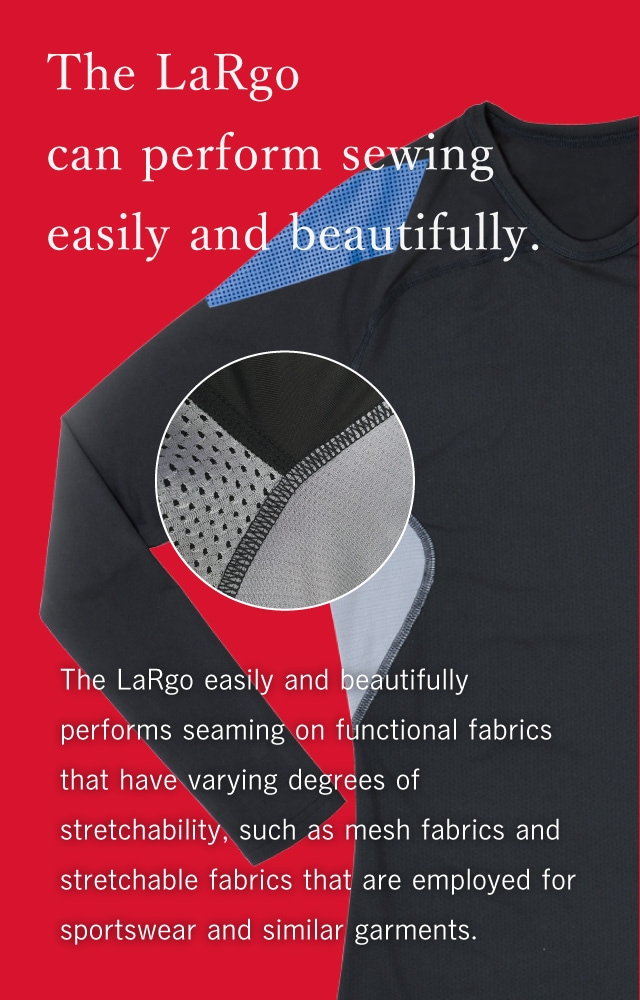

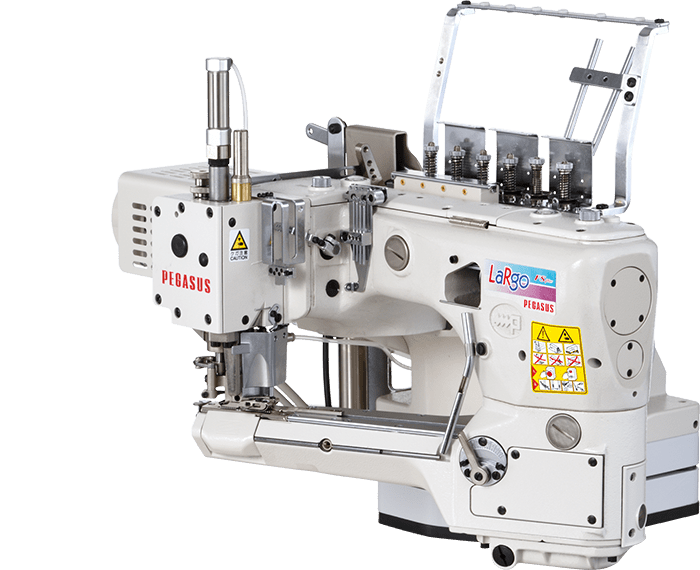

The LaRgo easily and beautifully performs seaming on functional fabrics that have varying degrees of stretchability, such as mesh fabrics and stretchable fabrics that are employed for sportswear and similar garments.

The operator does not require any special skills, such as the ability to perform sewing the fabric while stretching it properly. This flatseamer can maintain consistent quality on the finished products, regardless of the skill of the operator.

Accordingly, the loss of defective products is decreased and productivity is increased.

The LaRgo solves all of those kinds of trouble.

No matter what the circumstances, no matter the operator.

Needle and threads advance smoothly at the sewer’s own pace.

Stitching is straight and beautiful without worry.

This precise and soothing rhythm will

accurately guide those that follow.

LaRgo, with needle and thread, seams smoothly,

drawing on long cultivated technical skills and the daily genesis of imagination.

We move forward into the future together.

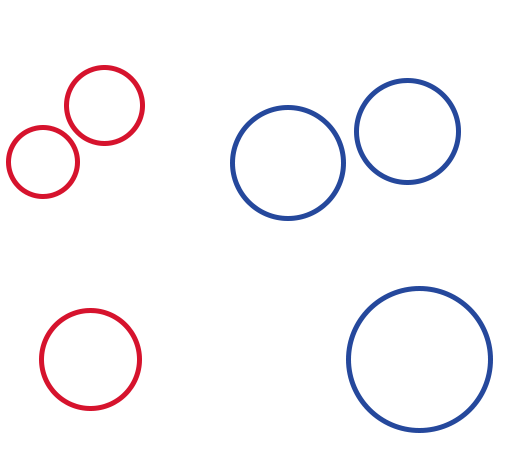

A standard feed mechanism feeds the same amount of the fabric consistently.

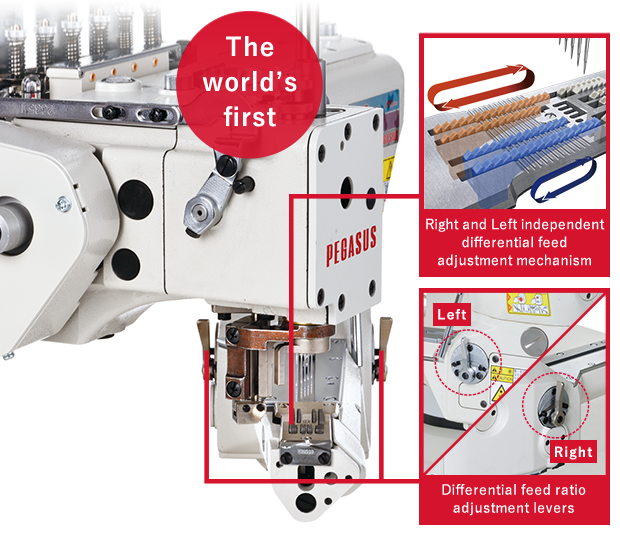

The LaRgo has a differential feed ratio adjustment lever on the right and left sides independently, which means that the LaRgo can adjust the differential feed ratio separately for the right and left hand sides.

Thanks to this feature, the proper feeding amount can be set and you will be able to sew up the fabric as you like.

Why do we give a nickname to the machine?

“Shall we sell a machine with a nickname?”

This idea came suddenly in summer, 2016 to the Sales Department.It seemed a shame to bury a machine equipped with the world’s first excellent equipment (a right and left independent differential feed adjustment mechanism) as one of subclasses. Taking this idea from a salesman, we decided to give this machine a nickname. This is the first trial in PEGASUS’ history.

* The nickname was decided as the “LaRgo.”

Why did we give this name to the new machine?

There were 100 candidates for the nickname when the idea started. We held meetings repeatedly, in order to decide the nickname.

The name “LaRgo” can be associated with a term in musical terminology that means “to play with the sound flowing. ”The key reason for this name was that the LaRgo comes from the initial letters of “Left and Right” included in the description of a left and right independent differential feed adjustment mechanism. In addition, the sound of“LaRgo” is good and easy to remember.

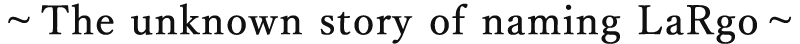

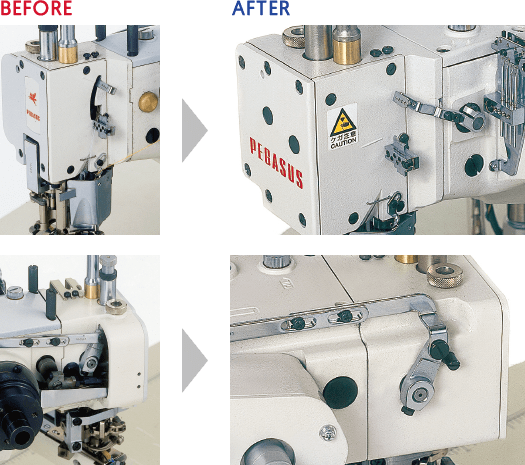

A face plate describes what the machine is like.

A face plate is like a machine name sticker that is stuck to each machine. The face plate is usually created by the department in charge. However, the face plate for the LaRgo is employed as one of the sales promotion tools. Therefore, the Sales Promotion Department also thought that this tool was important.

At first, we were planning to attach two face plates to the LaRgo, a face plate for the FS700P series and one for the LaRgo. However, the LaRgo is a flatseamer that has a unique shape. This means that the area is too small for these two face plates.

After much trial and error, the two face plates were united, and a one piece face plate only for the LaRgo was created.

Focusing on the design for the face plate

Every time each of 15 patterns was attached to the machine,

shooting a picture was performed, in order to repeatedly check the difference between the face plate on the real machine and that in the picture.

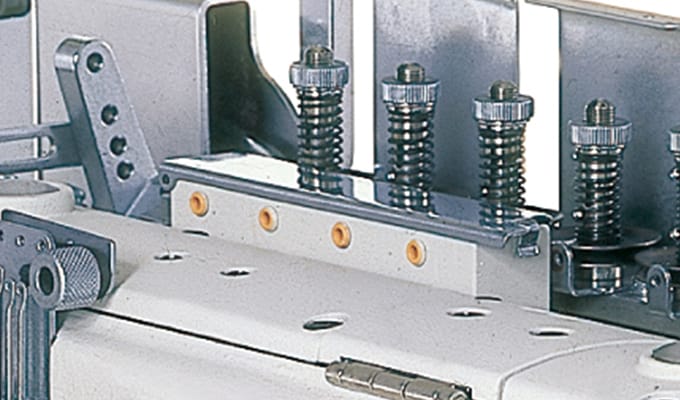

FS700P Series adopts the world’s first machine bed equipped with a completely enclosed needle drive mechanism.

FS700P Series is keeping high-quality and consistent stitches, and protects your important sewn products against oil stains, thanks to this high "Oil Barrier" effectiveness.

PEGASUS’ unique “Oil Barrier” technology protects your important sewn products from oil stains.

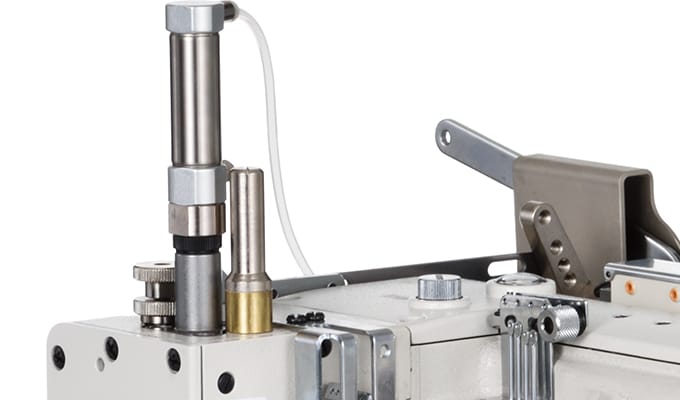

The uniform and most suitable presser foot pressure is always achieved according to the fabric.

This feature prevents seam jamming on cross seam sections, damage to the fabric, and shining appearing on the fabric, so this feature contributes greatly to stabilization and an increase in quality.

In addition, the presser foot pressure can be expressed in numerical form. Therefore, setting the presser foot pressure correctly for each fabric is easy, and the knife overlap pressure can be reduced simultaneously, increasing the durability of the knife.

Pressing the treadle with the heel raises the presser foot.

Ease of operation decreases operator fatigue.

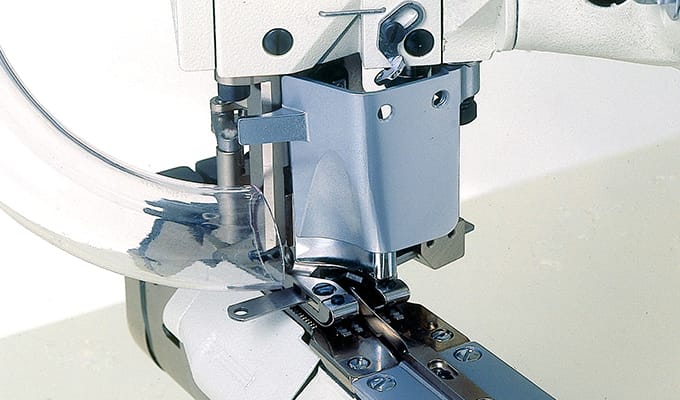

The HR device helps the needle thread run smoothly through the machine, forming uniform stitches.

A pneumatically operated device that cuts a thread chain.

No scissors are needed. Operating efficiency is dramatically increased.

This pneumatic device sucks up cutting waste generated during sewing, providing clean and comfortable working conditions.

Operators do not feel stress because of quick reaction when operation of machine running and stopping has been done.

Additionally it creates the best condition for the operation, since under the table is nothing to be disturbed.

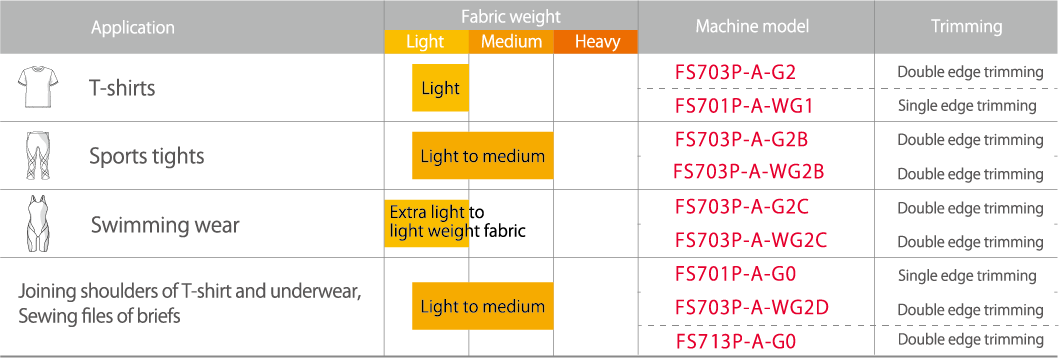

The LaRgo has a full line of subclasses that meet the needs of a diversified market.

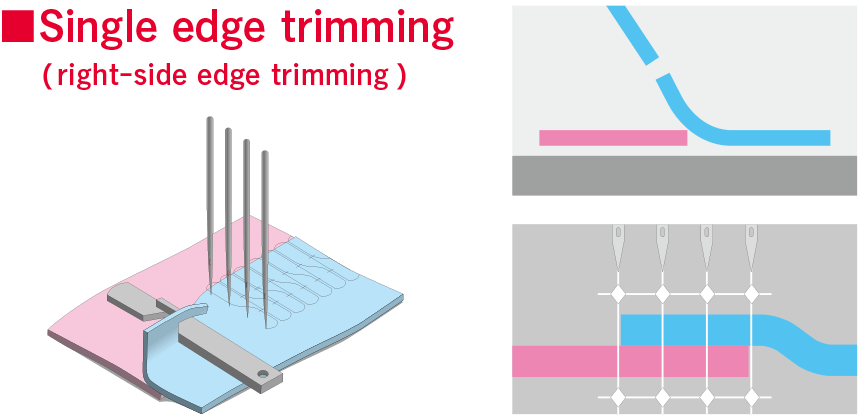

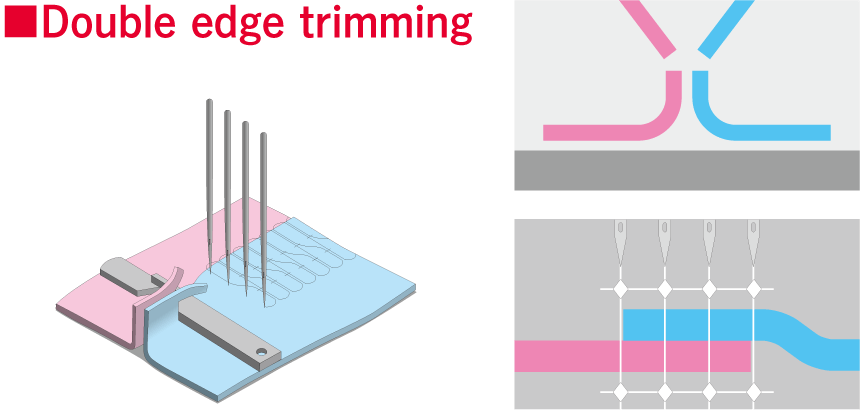

Two types of cutting for the fabric edge are available, single and double edge trimmings.

FS700P Series

Equipped with a right and left independent differential feed adjustment mechanism

Oil Barrier type, 4-needle, feed-off-the-arm, interlock stitch machines for flatseaming

※ Applications and/or fabric weights provide a rough indication, so how to sew the fabric depends on each sewn product.